Circular Resources

Many people are confused about the circular economy and believe it is primarily focused on recycling. Resource management and the efficient use of resources are critical if we are to live within the limits of our planetary boundaries. These are the foundations of the circular economy.

“A key component of the ideal industrial ecosystem is to increase resource efficiency through circulating material.”

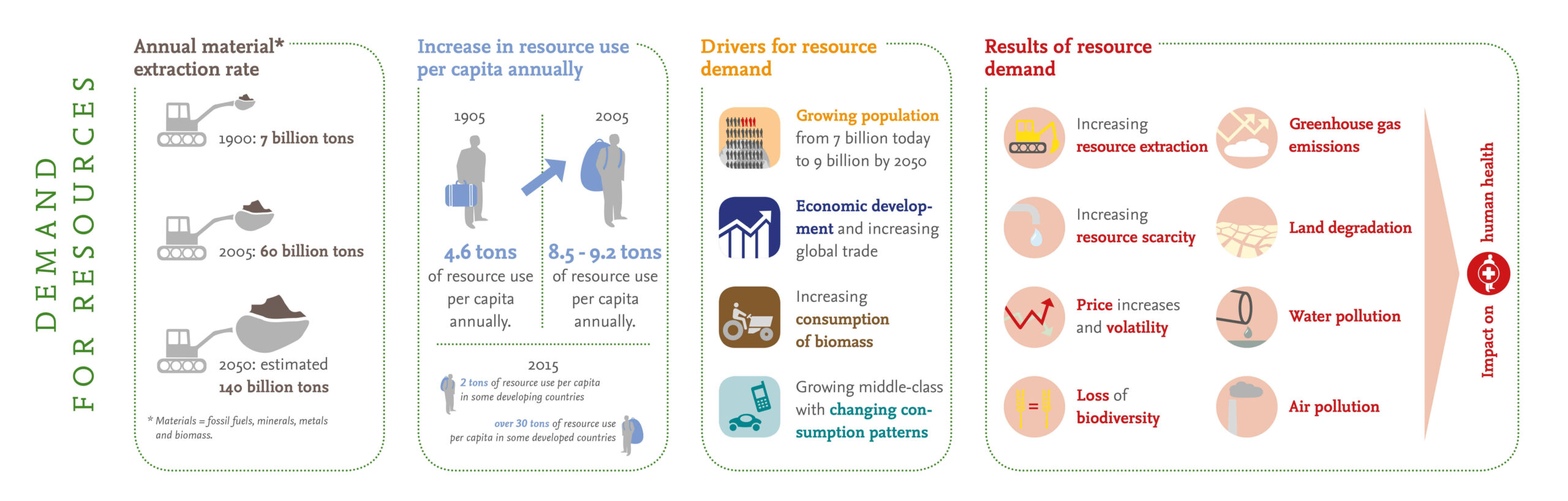

Resource Use to 2050

Unsustainable patterns of resource use need to be reconfigured or replaced by sustainable modes of producing and consuming that respect the capacity of the planet, meet people’s needs and improve human dignity. This calls for a process of structural transformation.

A projected 60 per cent growth in resource use by 2060 could derail efforts to achieve not only global climate, biodiversity, and pollution targets but also economic prosperity and human well-being.

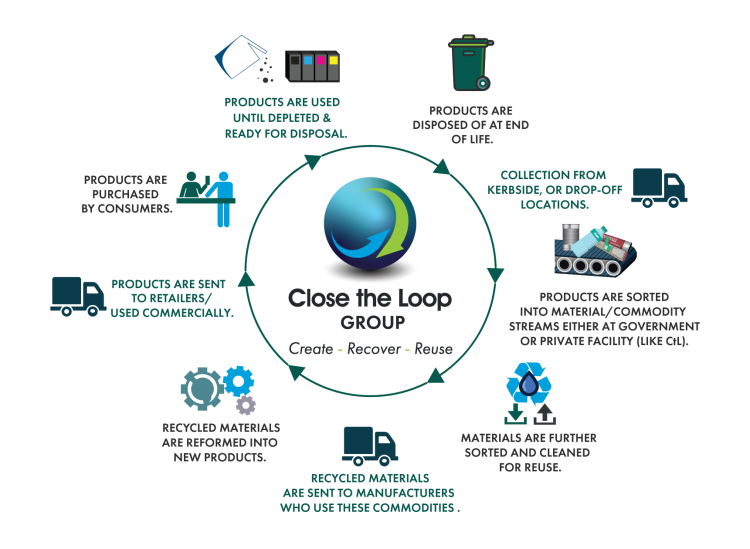

Closed-loop systems

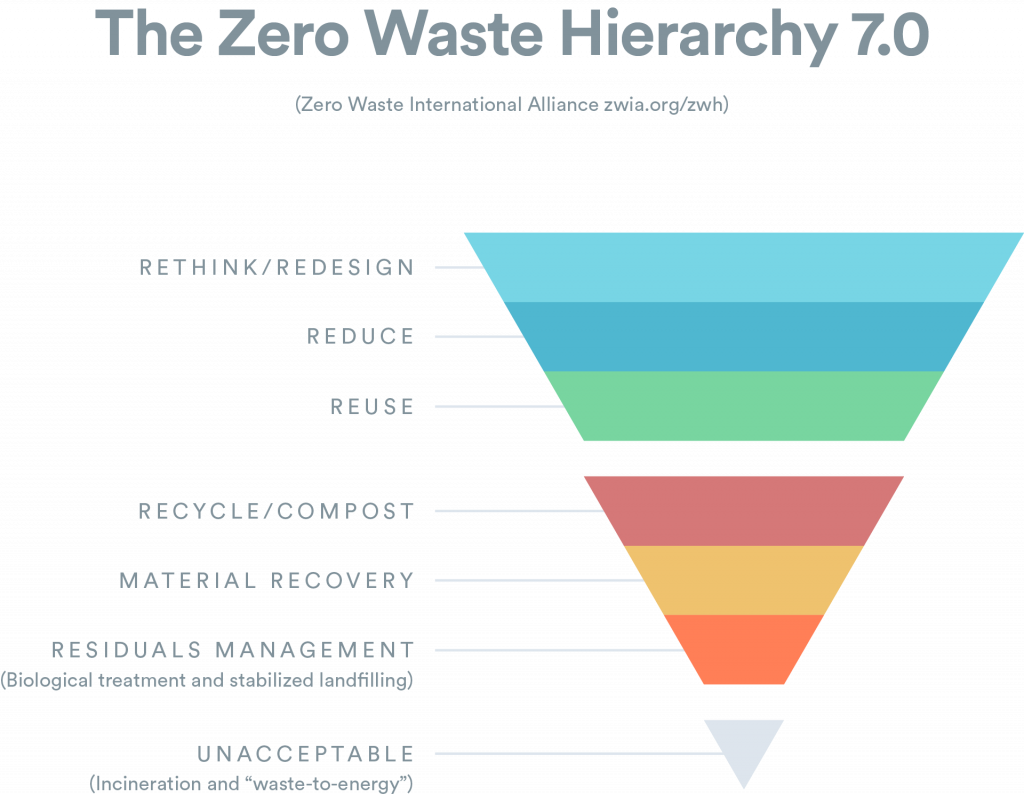

The aim of recovering end-of-use-cycle products is to keep in circulation the materials by integrating the Circular Rs as a standard business practice and establishing a structured secondary raw materials industry. While recycling mitigates resource depletion, physics imposes hard limits on its efficiency. A circular economy must prioritise reduction and reuse over recycling, as thermodynamics and material science make 100% recycling impossible.

Advances in material design (e.g., easily separable polymers) and industrial processes (e.g., laser sorting) can push these limits, but fundamental barriers remain.

A Strategy for Materials Management

Click on the link for more information on the Circular Skills Training. Download the Guide to Recyclable and Non-Recyclable Materials. Please note: The Guide is very much a work in progress, as the reprocessing industry is constantly evolving.

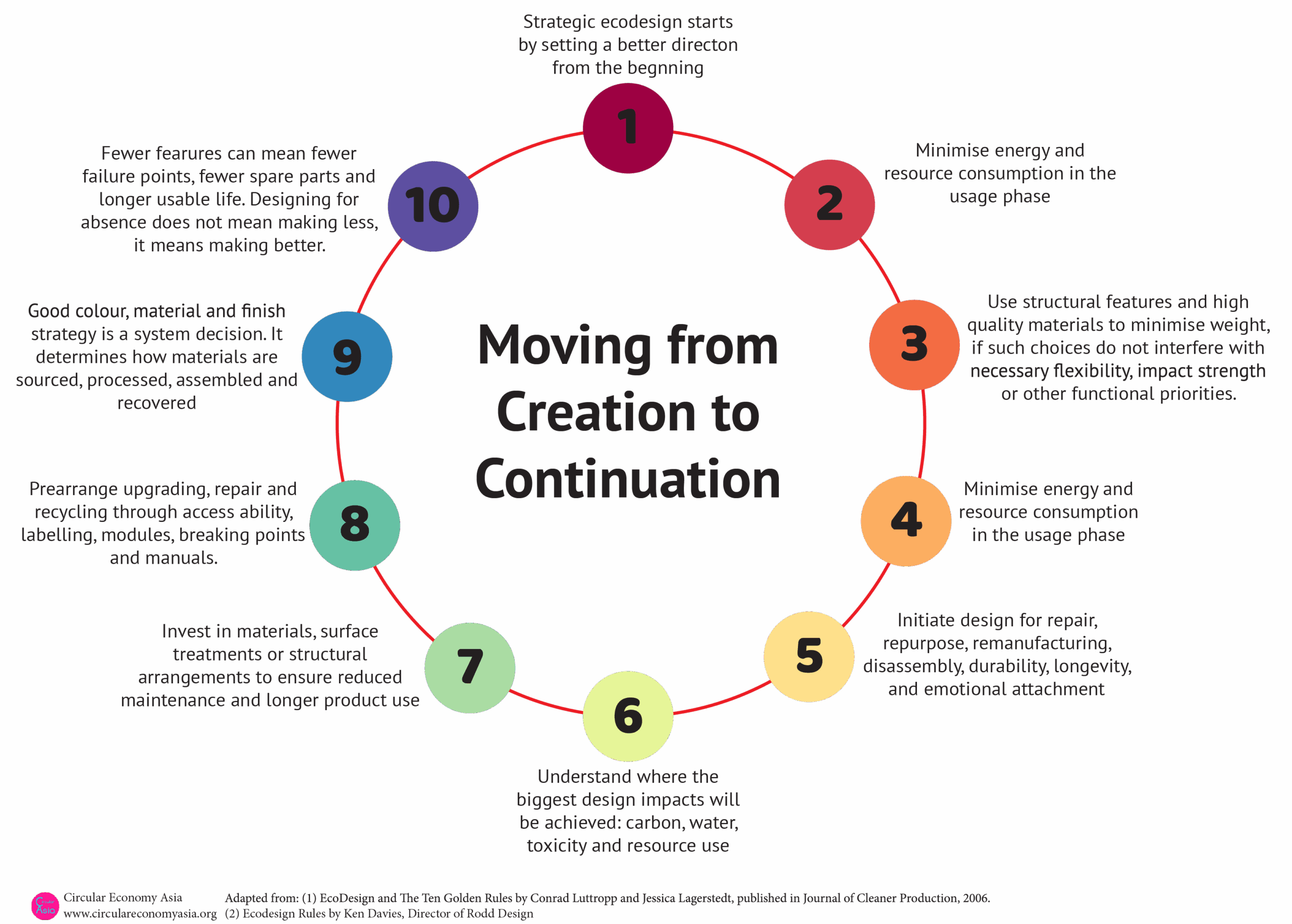

From Creation to Continuation

At a product’s earliest conception, selecting materials and how the product is designed will determine how this ‘resource’ will end up. The materials and design will decide how a product is used and passed on. There may be additional interactions with the product depending on the style (classic or fast-fashion), reason or emotional attachment. For example, we may buy a piece of clothing only for a special occasion. Or a kitchen utility that can last for many years.

We mainly prolong the use-cycle of a product because we are emotionally attached or based on an economic decision (it may be cheaper to repair than buy new). We seldom consider the product as a resource and dispose of it accordingly.

Eco-design is a strategic design management approach to reducing environmental impacts across the whole product life cycle.

The European Commission defines eco-design as “…taking into account all of the environmental impacts of a product right from the earliest stage of design. In particular, this avoids uncoordinated product planning, for example, eliminating a toxic substance should not lead to higher energy consumption, which on balance could have a negative impact on the environment.”

Traditionally, eco-design definitions focus on products but have evolved to include services and systems.

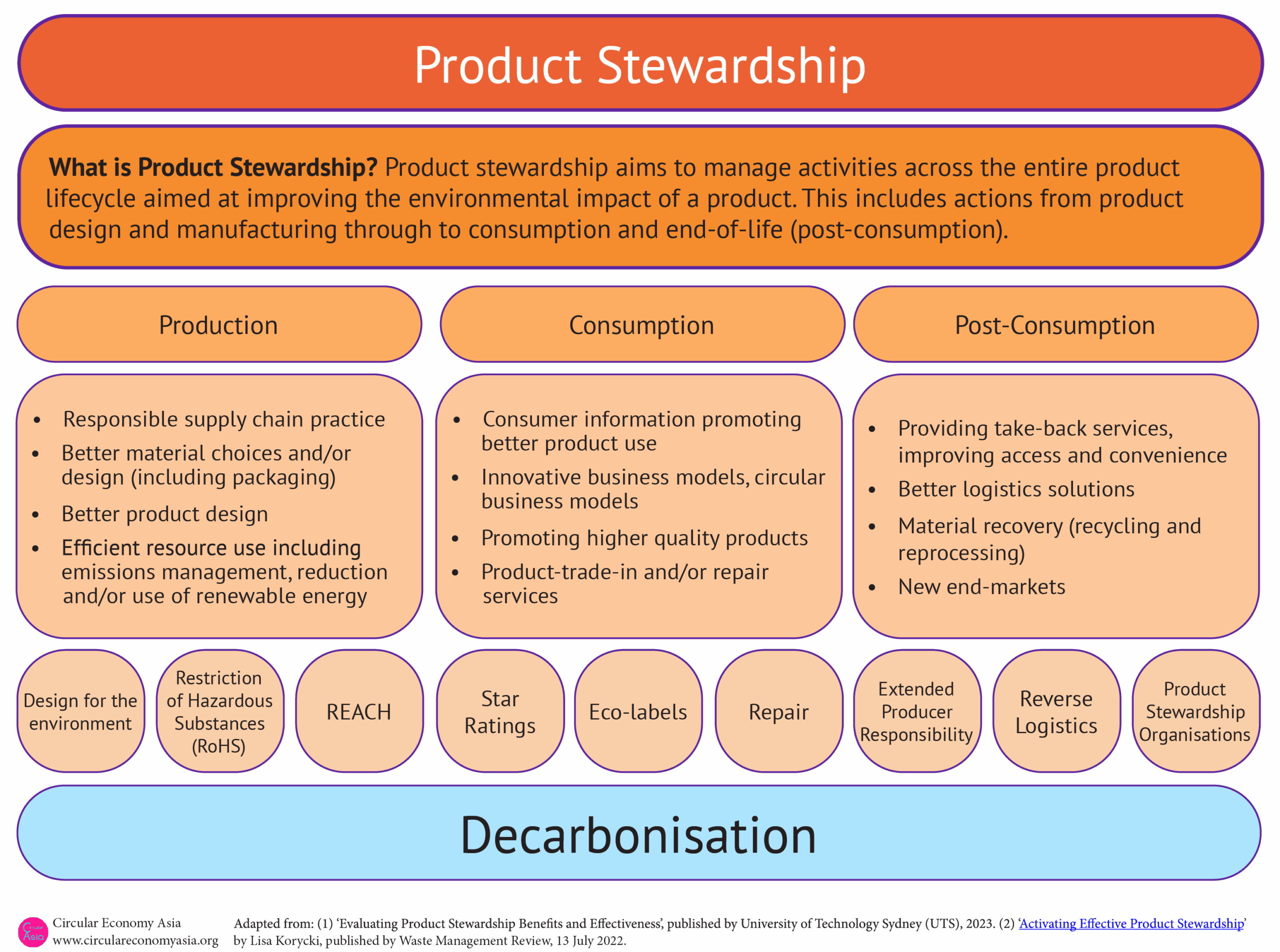

Product Stewardship

In the circular economy, resource management can be achieved through product stewardship. Product stewardship acknowledges that those involved in designing, manufacturing, and selling products have a responsibility to ensure those products or materials are managed in a way that reduces their environmental and human health impacts throughout the use-cycle and across the supply chain. Product Stewardship aims to reduce waste generation through better design and manufacture of products, product use-cycle extension, including the use of materials that are easier to recover, reuse and recycle.

Types of Product Stewardship

Collective schemes – Multiple businesses placing similar products on the market work collaboratively to deliver product stewardship solutions that address industry-wide challenges. Collective schemes can be led by an industry association, a product stewardship organisation (PSO), or an industry collective.

Individual business initiatives – Led by a single business or brand, these are often managed internally and may involve other supply chain actors. They can include activities such as designing for circularity and providing opportunities for repair, reuse, sharing and takeback schemes.

Zero Waste & Zero Waste to Landfill

The concept of Zero Waste has been around for quite a long time. The goal of Zero Waste to Landfill has become increasingly popular, especially since ESG reporting has become more widespread. There are also a growing number of organizations that offer verification services on a company’s ability to achieve Zero Waste to Landfill or Near Zero Waste to Landfill.

According to the Zero Waste International Alliance, the definition of zero waste is “The conservation of all resources by means of responsible production, consumption, reuse, and recovery of products, packaging, and materials without burning and with no discharges to land, water, or air that threaten the environment or human health.” Sounds a lot like the circular economy?

We need to be careful about the goal of Zero Waste to Landfill. Even with the most efficient systems in place, some materials are inevitably sent to landfill at some point downstream of the waste treatment. For example, energy recovery will lead to the production of residual waste in the form of ash. And some regulated hazardous substances must be sent to landfill, because there are no other legally permitted alternative waste treatment methods.

There is also the issue of fraud in waste management. This may mean that even the best of intentions, some part of an organisation’s waste may end up in landfill without its knowledge. Although to mitigate the risk of fraud, businesses should choose good quality waste management partners and conduct regular audits.² In the circular economy, the current hinderance is the lack of adequate processes and facilities to divert recovered resources where it can be categorised for any one of the Circular Rs.

The Law of Supply and Demand

When we see mountains of waste, all too often we think this is the problem we have to solve. Although collection systems and infrastructure remain weak or non-existent in many countries, we have the technology to manage most of it, even if the economics requires scale.

The real challenge is the demand side. Many products made from secondary raw materials have a ‘green premium’ making them more expensive than products manufactured from virgin resources. Or there is a perception around poor quality. Thus demand remains low and the solution to a healthy secondary raw materials industry is in a robust demand-driven market.

What is a commodity? A commodity is a basic good or raw material used in commerce that is interchangeable with other goods of the same type. Commodities are typically used as inputs in the production of other goods or services.

What is Exchange Trade? Exchange trading refers to the buying and selling of financial instruments (like stocks, bonds, commodities, or derivatives) through a centralised marketplace called an exchange. These exchanges provide a regulated, transparent, and organised platform where buyers and sellers can trade assets at publicly quoted prices.

In commodity markets, supply and demand dictate prices, while exchanges provide the platform to trade these expectations. A secondary raw materials industry can operate as a commodity on exchange trade platforms. While scrap itself is not typically traded as a standardised futures contract (unlike refined metals), its pricing and markets are indirectly linked to commodity exchanges. Can secondary raw materials, for plastics, textiles, glass, paper/cardboard and organic materials industry function in the same way?

References:

What is Zero Waste to Landfill?” by The Carbon Trust, 14 March 2017

Image: Commodity & Exchange Trade – Designed by macrovector / Freepik

Image: Demand for Resources – UN Environment Program, 2011