Supply Chain

Supply Chain for a Circular Economy

Ask yourself what would happen if your company could no longer source the raw materials to manufacture the products you sell and we consume? Or your supplier could no longer deliver the products your business needs to function due to climate change disruption, resource price volatility or raw material costs keep increasing due to limited supply?

All companies need to adapt to the challenges of the future, including raw material supply risk, price volatility, climate change and consumers demanding companies become more sustainable.

What is a Circular Supply Chain?

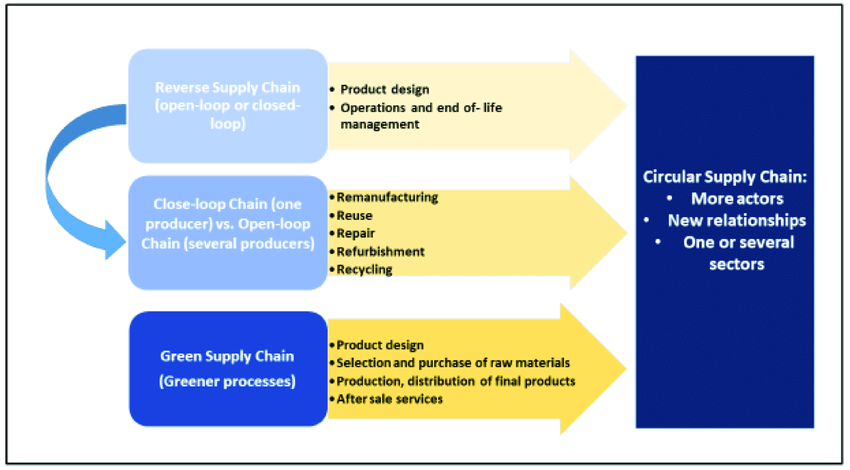

The starting point is that all economic growth is directly related to flows of materials and energy. Therefore, the circular economy focuses on avoiding, minimising, restoring, and/or compensating stakeholders. The application of circularity in the supply chain has two main pillars. One is based on extending the durability of products or increasing remanufacturing, repair, renovation, and reprocessing cycles. The second is the extension over a period of time where materials are kept in use for as long as possible.

The current competitive environment requires companies to be innovative in their production systems and to rethink the current use of resources and waste management. Circular productive systems must produce higher yields by using fewer resources and also results in fewer CO2 emissions. This circularity also extends to companies’ supply chains, because of the key role it plays in their performance.

Providing action guidance to companies would promote success in incorporating the circular philosophy into supply chain systems, both intra-company and beyond company boundaries.

Four dimensions have been identified to support the development of these new supply chains:

(1) Greater intensity in the relationships established in the supply chain – successful circular supply chains will require integrated cooperative actions by all stakeholders and a multi-sector approach supported by improved flows of knowledge and increased transparency.

(2) Adaptation of logistics and organizational – reverse logistics encourage the return of material via the producer and industrial symbiosis favours the exchange of waste between industrial partners. But the transformation goes much further. It requires the design of circular business models. Circular business models are a more complex and narrow type of business model innovation than a sustainable business model since the latter not only creates sustainable value but also involves dynamic management of the loops of resources.

(3) Disruptive and smart technologies – New technologies allow the development of new functionalities necessary for productive and management change. The main role of information and communication technologies is the application of push and saving impacts to optimize the economic processes of production, consumption and circulation. So, technology development toward a circular economy in three fundamental aspects:

(a) The production – for example, the reprocessing of waste, and cogeneration systems (the generation of electricity and useful heat jointly, especially the utilization of the steam left over from electricity generation for heating), product design, manufacturing, and remanufacturing processes;

(b) The stakeholders – for example, predictive analysis and the exchange of information; and

(c) The information – through the Internet of Things (IoT) and the Internet of Services, information is monitored, controlled, and transferred.

(4) A functioning environment – A holistic framework helps companies ensure they are more environmentally-conscious in circular supply chain activities and provides a roadmap in terms of environmental, economic, logistical, operational, and organizational activities [16] to adopt circular supply models effectively.

(Source: ‘Main Dimensions in the Building of the Circular Supply Chain: A Literature Review‘ by Rocío González-Sánchez, Davide Settembre-Blundo, Anna Maria Ferrari, and Fernando E. García-Muiña, published in The Journal of Sustainability, March 2020)

Supply Chain for a Circular Economy Workshop

The Supply Chain for a Circular Economy workshop is a full-day workshop covering several important themes to bring your supply chain along your circular journey. Visit the Supply Chain Workshop page to learn what is included in this class.

We have a selection of workshops to choose from, starting with our ½ day mini-series for busy people or the deep-dive 1 or 2-day workshops. Visit The Nine Steps Towards a Circular Business™ to review the current selection of workshops on offer.

Knowledge Centre

This section includes many very informative documents, reports, articles, infographics, IoT, logistics, outsourcing, procurement, samples of supplier questionnaires and score cards, SMART (Specific, Measurable, Achievable, Relevant and Time Limited), supply chain visibility, sustainable supply chain, technology and tools.

References:

- Supply Chain: Supply Chain by Becris from The Noun Project

- Knowledge Centre: Freepik from Flaticon

- Information: CleanPNG

- Video: Freepik

- Links: Icon Finder