Closed Loop

Closed Loop Systems

A closed-loop system is the basis for the circular economy and offers the best options to manage our finite natural resources. However, it is important to note that, currently, the world is a very long way from managing our primary raw materials adequately. Establishing a closed-loop system prioritises the design, material health of a product, the manufacturing processes, energy type and usage, plus other resource inputs.

In addition, a closed-loop system is concerned about the total life-cycle including the outcome at the end of the final use-cycle. Products can be designed to be part of any one of the Circular Rs. For example, a product can be designed to be repairable and durable. Access to the product may be through innovative business models or Product-as-a-Service usage systems. End-of-use-cycle value can be optimised through material health, take-back schemes and ease of disassembly for reprocessing.

Many cases of reprocessing only help postpone permanent waste generation. This happens if an original material gradually loses its quality while being reprocessed and cannot return to the same manufacturing state. It has to be manufactured to lower-grade products, which are not necessarily recyclable. This way of recycling, when a material lives a few lives but becomes less and less usable or pure or safe along its way to the landfill, is often termed “downcycling”. In terms of sustainability, it means being “less bad”, but still not good enough.

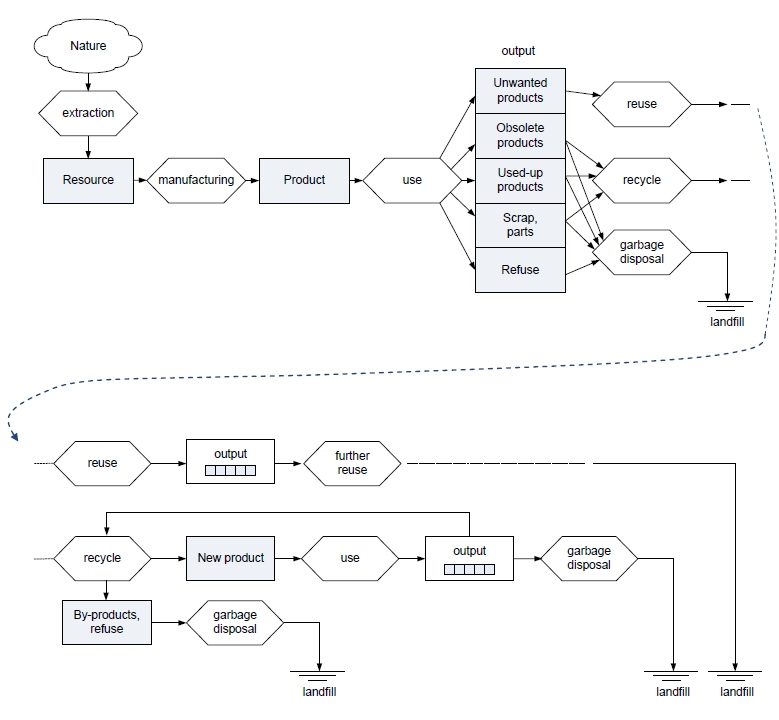

Open Loop System

Open-loop recycling basically means that a material is not reprocessed indefinitely and is eventually excluded from the utilization loop and becomes waste. In the diagram opposite, natural resources are extracted from the environment and transformed into a product via the manufacturing process.

After its use, the product may be discarded as one of the outputs:

(a) Whole product that is not needed anymore;

(b) Whole product that became obsolete (although still functional);

(c) Non-functional or old product because of its limited lifetime;

(d) Recyclable / reusable parts or scrapped materials; and

(e) Non-reprocessable refuse.

Those outputs enter one of the post-use channels – reuse, recycle, and garbage disposal, the latter contributing to the landfill. Reuse channel is usually limited, just postponing garbage disposal. Recycling loop results in producing another material, which is typically of lower grade and purity than the original material. It may be transformed further into a different product, which after use creates similar outputs. In the long run, a small part of the original resource may be stuck in the loop, but the majority of it becomes disposed of.

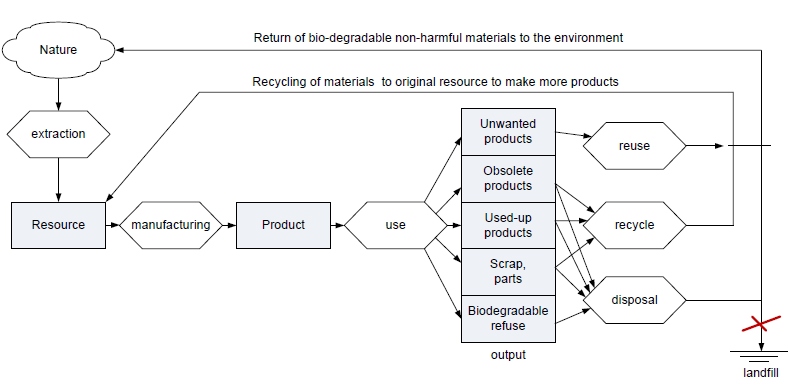

Closed Loop System

Closed-loop systems can also be called ‘Cradle-to-Cradle®’ – whereby industrial products never find their way to ‘the grave’ or landfill but are continuously ‘kept in the loop’ being reprocessed and reused. Products are being designed not only to have a long life to ensure they remain in circulation but also able to be regenerated and recycled once they have exhausted their first useful life. The more materials that can be kept in the loop, reclaimed and reprocessed, the less needs to be extracted from the planet.

Closed-loop systems are a more sustainable concept, which means that reprocessing of a material can be done indefinitely without degradation of properties. In this case, conversion of the used product back to a raw material allows for the repeated manufacturing of the same or a different product over and over again.

A few things to consider:

- The recycled materials should provide the same quality of the product (no deterioration). For example, almost all recycled aluminium from soda cans is suitable to produce the same cans.

- There should be no accumulation of contaminants or toxins in the multiple recycling loops, which can make the secondary product less safe.

- The recycled material can also feed the manufacturing process for a different product or industry, which may require a different type of recycling.

(Source: Images and text: Recycling: open-loop versus closed-loop thinking, Penn State University, Mark Fedkin)

Knowledge Centre

In this section there is a small number of documents and images. There are several videos in the Circular Economy YouTube Channel Closed Loop playlist.

References

- ‘Cradle-to-Cradle – Carpets and Cities’ by Dr David A Ness and Michael S Field, CSIRO Sustainability Network, published 2004.

- Infinity icon: Freepik from Flaticon

- Knowledge Centre: Freepik from Flaticon

- Information: CleanPNG

- Video: Freepik