Mechanical Recycling

Mechanical Recycling

Mechanical recycling of plastics refers to the processing of plastics waste into secondary raw material or products without significantly changing the chemical structure of the material. In principle, all types of thermoplastics can be mechanically recycled with little or no quality impairment.

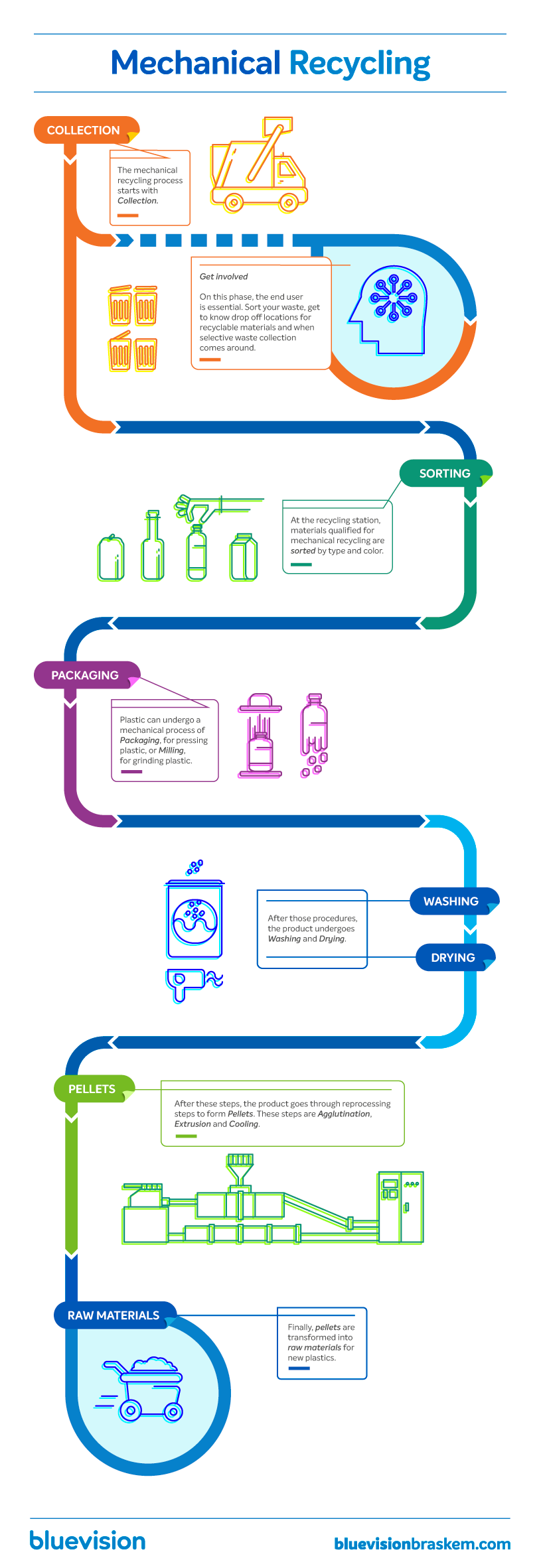

Before recycling, most plastics are sorted according to their resin type. In the past, plastic reclaimers used the resin identification code (RIC), a method of categorization of polymer types, which was developed by the Society of the Plastics Industry in 1988. Polyethylene terephthalate, commonly referred to as PET, for instance, has a resin code of 1. Most plastic reclaimers do not rely on the RIC now; they use various sorting systems to identify the resin, ranging from manual sorting and picking of plastic materials to mechanized automation processes that involve shredding, sieving, separation by rates of density i.e. air, liquid, or magnetic, and complex spectrophotometric distribution technologies e.g. UV/VIS, NIR, Laser, etc. Some plastic products are also separated by color before they are recycled.

After sorting, for mechanical recycling the plastic recyclables are then shredded. These shredded fragments then undergo processes to eliminate impurities like paper labels. This material is melted and often extruded into the form of pellets which are then used to manufacture other products. The highest quality purification may be referred to as “regeneration”.

Products Made from Mechanical Recycling

The benefits and challenges of mechancial recycling

Benefits

1. Recycling plastic conserves the natural resources and energy that is required to produce virgin plastic.

2. When plastic is recycled, less plastic is sent to landfill and thus, less of this material takes up room in our environment for hundreds of years.

3. Making new products from recycled plastic packaging materials is more than three times more efficient in terms of greenhouse gas emissions than manufacturing those same products with virgin raw materials, mainly because of the energy savings in recycled versus virgin content product manufacturing.

Challenges

1. The quality of plastics collected (the feedstock for recycling processors) is, usually, inconsistent and contaminated leading to downcycling into lower value items.

2. Many plastic recycling companies have insufficient standardization, industrialization and operational excellence in their operations. This is largely due to the nature of the sector, which is characterized by small, entrepreneurial companies, with management teams that often have limited experience in the professional plastics industry.

3. In reality, only a fraction of ‘recyclable’ used plastic is recycled into the products for which they were originally produced, even in the case of the most readily recyclable plastic such as PET and HDPE. The challenges are due to colorants, additives, and fillers used during plastic production, contamination from consumer use, and yield losses during the recycling process.

Even if plastic were recycled despite all the barriers, each cycle of the recycling process shortens the length of polymer chains, resulting in quality loss and, eventually, the need to dispose of the material. Lower-grade plastic waste, including post-consumer and multi-layered plastic packaging is particularly difficult to separate and process.

4. Plastic recyclers tend to specialize in one or a limited number of plastic types such as HDPE, LDPE and PP, to name a few. Recyclers produce regranulates for industrial buyers, with whom they agree various quality standards around criteria such as density, melt-flow index and stability.

In order to guarantee product quality and quantity, plastic recyclers seek plastic waste bales with specific criteria. These often need to be sourced from various countries, which can be challenging due to the different collection schemes and sales methods for plastic waste.

Additional information

For more information on chemical recycling, recyclable resources and reprocessing visit the Knowledge Centre to access reports, research, videos, infographics, articles and images covering 50+ different topics.

References

- Recycling image: Freepik from Flaticon

- Plastics Europe: Recycling and Energy Recovery

- Wikipedia: Plastic Recycling

- ‘The Plastic Recycling Opportunity’ published by KPMG International Cooperative, 2019

- ‘Plastic & Climate’, published by Center for International Environmental Law, 2019